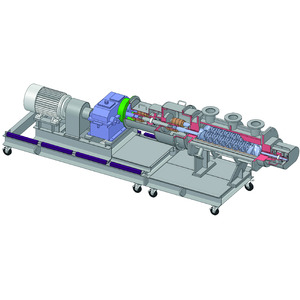

KRC Hybrid Reactor / Twin Screw Continuous Reacting Processor

Division for this product Divisi Plant Engineering & Machinery

Outline

|

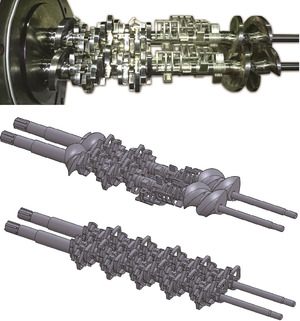

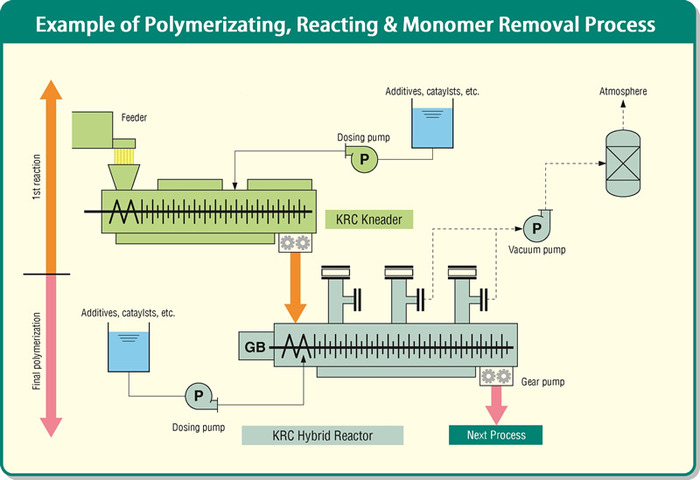

Continuous Processor for Reaction (Polymerization, Poly-condensation, Emulsion, Solution polymerization), Monomer Removal, Devolatilization and Deaeration The KRC Hybrid Reactor has been added to KURIMOTO's product lineup. This new reactor is the next level in enhanced performance from our holdup-type reactors, and is based on KURIMOTO's knowhow for its twin-screw continuous-type kneader (KRC Kneader) gained over many years. The KRC Hybrid Reactor has excellent basic performance in areas such as high-viscosity continuous processing, maintaining long residence time and piston flow characteristics (narrow residence time distribution). |

Features

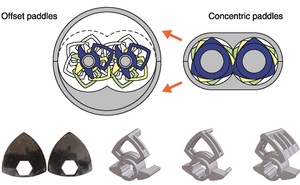

Long Residence Time Performance The uniquely-shaped offset paddles with small paddle diameters provide large rotational radius. Excellent Piston Flow Characteristics and Self-Wiping Performance Enable to obtain sharp residence time curve and homogeneous reaction processing. Large Surface Renewal Effectiveness and Degassing Structure Enable to form the large gas-liquid interface and surface area, and achieve excellent accelerated reaction effect. Enable to adapt for large quantity output Effective capacity: 2L - 50,000L Operation under high temperature and high vacuum condition Temperature: ~350℃ Outstanding product discharge performance Enable to stable discharge of high viscosity products * If required excellent mixing and dispersion capability, KRC Kneader (Continuous Kneader / Reactor) would be a solution. |

|

Keyword

Customer topic

Applications

Examples of applications

Reaction (Polycondensation, Bulk polymerization, Emulsion, Solution polymerization etc.)

Polyamide resinsPolycarbonate resins Esterification reaction (Polyester, PLA etc.) Super absorbent polymer Acrylic resins Vinyl acetate resins Polybutylene terephthalate |

Monomer removal and devolatilization

Special olefine series (PS and PE series) materialsPolyamide PET, etc. |

|

DeaerationSealing materials |

Continuous reactors for high viscosity polymers

(Polycondensation, Bulk polymerization, Emulsion, Solution polymerization etc.)

Monomer removal and devolatilization in ppm order

Replacement from Batch process to Continuous Process (Process Improvement)

As the finisher or preliminary polymerizer in various processes

Details

Sample Flow

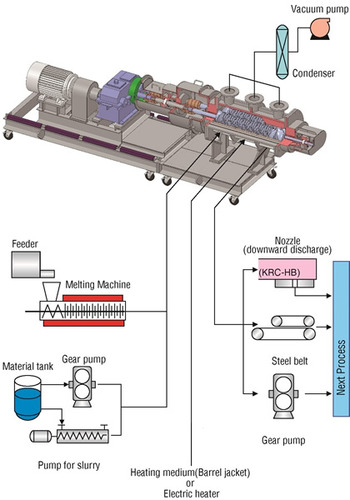

KRC Hybrid Reactor has several options of discharge methods (Nozzle, Vacuum tank, Gear Pump etc.) and can transfer to the next process.

Discharge methods are decided from products property (powder and granular material, strand material, high viscosity paste etc.)

Sample Test Flow

Three Size (2L, 8L and 65L) of KRC Hybrid Reactor as test machines are installed in our Machine and Technology Center in Sumiyoshi Factory, Japan and trials are aveilable under high vacuum and high temperature condition with your raw materials.

If you have any inquiries about kneading, reaction, and granulating tests, please feel free to contact us anytime.

Keyword

Applicable processes

Division for this page Divisi Plant Engineering & Machinery