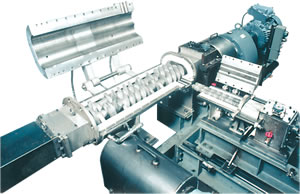

Continuous Kneading & Reacting Processor KRC Kneader / Reactor

Division for this product Divisi Plant Engineering & Machinery

|

Summary

|

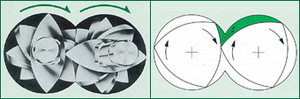

* Click here to enlarge the figure & Kneading mechanism. * Click here to enlarge the figure & Kneading mechanism. |

Features / Advantage

- Excellent continuous kneading performance

- Unlimited arrangement of paddles

- Self-wiping action

- Available for wide range viscosity

- Small footprint maxmizes floor space

- Easy operation and maintenance

Application

General chemical products

- SEALANTS(for automobile or architecture etc.)

- ADHESIVES(for automobile etc.)

- AGROCHEMICALS

- EPOXY(RESIN)

- CATALYSTS(for denitration etc.)

- CELLULOSE(CMC, MCC etc.)

- PIGMENT

- PHENOL(RESIN)

Chemical reaction

- ENGINEERING PLASTICS

- HOLLOW-FIBER MEMBRANES

(for kidney dialysis or seawater) - FIBERS(Cotton linter etc.)

Resin products

- COMPOSITES(Resin & powder etc.)

- EPOXY MOLDING COMPOUNDS

(encapsulating materials for semiconductor devices) - CONDUCTIVE RESINS

- PLASTIC MAGNET(for refrigerator)

- TONERS

- MAGNETIC PAINT

- POWDER COATINGS

- ARTIFICIAL MARBLE

- PLASTIC LENZ(for facsimile or photocopier)

Ceramic and Inorganic material

- BATTERIES(Li-ion, Ni-Cd, Alkaline)

- CERAMICS CONDENSER

- FIREPROOF MATERIALS

- GRAPHITE SPECIALTIES

- ACTIVATED CARBON

Foods, Agricultural products and Pharmaceuticals

- CHOCOLATE

- DOUGHS(for cookie, cracker etc.)

- COFFEE

- SEOSONINGS(Soybean paste)

- STEAMED FISH PASTE

- SOFT CANDY

- ARTIFICIAL SWEETNER(Sorbitol, Multitol)

- BUTTER

- PET FOODS

- PHARMACEUTICALS

(Stomach powder, Throat lozenge)

Waste disposal Mining and Coal products

- FUEL(CWM-coal slurry, Ethanol)

- REFUSE INCINERATION ASH

- SEWAGE SLUDGE CAKE

Typical Flow

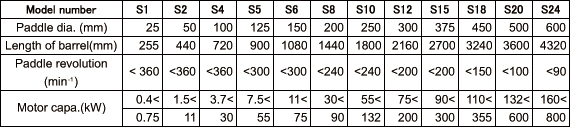

Specifications of S-type

T-type KRC Kneader (High Torque Type)

T-type KRC Kneader is suitable for kneading & mixing material which can not be handled by S-type KRC Kneader and needs higher horsepower.

Horsepower per unit volume is 6-7 times compared to S-type KRC Kneader.

Specifications of T-type

| Model number | T2 | T4 | T5 | T6 | T8 | T10 | T12 | T15 | T18 |

|---|---|---|---|---|---|---|---|---|---|

| Paddle dia. (mm) | 50 | 100 | 125 | 150 | 200 | 250 | 300 | 375 | 450 |

| Length of barrel(mm) | 440 | 720 | 900 | 1080 | 1440 | 1800 | 2160 | 2700 | 3240 |

| Paddle revolution (min-1) |

< 360 | <300 | <300 | <240 | <240 | <200 | <200 | <150 | <100 |

| Motor capa.(kW) | 3.7< 22 |

15< 75 |

30< 110 |

45< 160 |

90< 300 |

150< 450 |

200< 600 |

355< 900 |

500< 1200 |

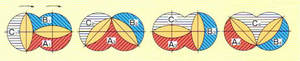

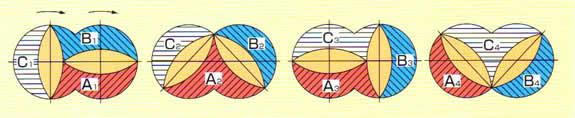

Kneading mechanism

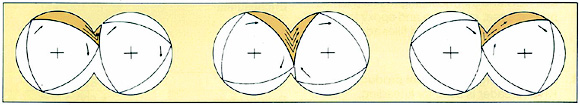

- The paddles can be changed individually. Therefore the optimum paddle arrangement pattern can be selected according to the application and purpose.

These selections of paddle arrangement enable the Kneader to control residence time and axial pressure distribution of the materials. - Paddles rotate so that one paddle wipes the tip of another paddle in rotation, preventing build up of material to the paddle.

- Volume of material is changed in compression and expansion according to paddle's rotation.

Shearing actions between the barrel and paddle, and between paddles increases efficiency of kneading and dispersion.

Heating or cooling system

- Jackets provided in the upper and lower barrels can control barrel temperature by circulating heating or cooling medium.

- Temperature is applied up to 350 Celsius degree by heating medium.

Standard driving system

- Either single speed motor or variable motor can be used.

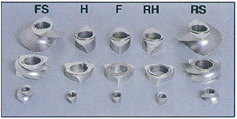

Paddles and screws

|

|

Two types of screws and three types of paddles are available.

|

|

|

Example assembling of paddles and screws

BARREL

Three types of barrels are available.

Division for this page Divisi Plant Engineering & Machinery