New lead-free copper alloys (Kurika Bronze)

Note : Isi dari halaman ini ditulis dalam Bahasa Inggris

【Special Permit No.3946244】

Features

- Reduces defects during casting (compared to our company's products)

- Inclusion of nickel is excellent for pressure resistance. Suitable for thick-walled cast metal as well.

- Casting design is made possible by conforming to JIS H5120 CAC406 standards

- Through the balance of Ni-P-Sn levels, has excellent machinability and workability through the balancing of Ni-P-Sn levels

- Environmentally-friendly chemical components. (Selenium, Antimony-free copper alloy)

- Mechanical properties conform to JIS H5120 CAC406 standards

Chemical Components

1.5 to 3.0 nickel is added to Cu-Sn-Zn-Bi-P

Graph 1 Major Chemical Components (by wt%)

| Type | Ni | Sn | Zn | Bi | P | Pb | Cu |

|---|---|---|---|---|---|---|---|

| KURIKA BRONZE Ingot JIS H2202 CACIn904 |

1.5-2.5 | 3.0-5.0 | 6.0-9.0 | 1.0-2.0 | ≦0.03 | ≦0.1 | Bal. |

| KURIKA BRONZE Casting JIS H5120 CAC904 |

1.5-2.5 | 3.0-5.0 | 6.0-9.0 | 1.0-2.0 | ≦0.05 | ≦0.25 | Bal. |

| KURIKA BRONZE Continuous Casting JIS H5120 CAC904C |

1.5-2.5 | 3.0-5.0 | 6.0-9.0 | 1.0-2.0 | ≦0.5 | ≦0.25 | Bal. |

| CDA C89845 | 1.5-2.5 | 3.0-5.0 | 6.0-9.0 | 1.0-2.0 | ≦0.05 | ≦0.09 | Bal. |

| Chemical Composition Example |

1.7 | 4.0 | 7.0 | 1.7 | ≦0.05 | ≦0.25 | Bal. |

Mechanical Properties

Mechanical properties conform to CAC406.

Machinability

- Concerning the machinability coefficient, on the condition that of CAC406 is 100, the Kurika Bronze is from 80 to 90.

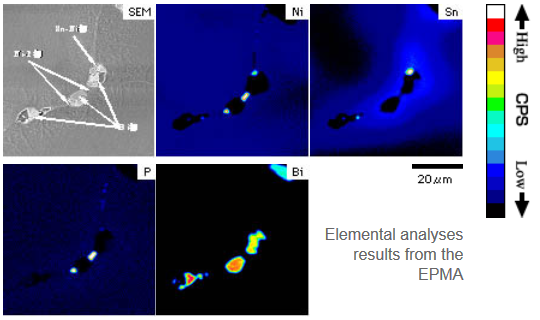

- The superior Machinability, because of Bi-Ni compound-containing.

- Chip Shapes are fine, and conventional machining method could be applied.

CAC406C |

Kurika Bronze |

Why the inclusion of Ni?

With the inclusion of Ni, Ni-Sn compounds and Ni-P compounds are generated around the Bi atoms, thus improving pressure resistance and cutting performance.